HIGH AND LOW SIDE DRIVER Product Summary VOFFSET (IR2110) 500V max. (IR2113) 600V max. IO+/- 2A / 2A VOUT. Description The IR2110/IR2113 are high voltage, high speed power MOSFET and IGBT drivers with independent high and low side referenced output chan-nels. Proprietary HVIC and latch immune CMOS technologies enable. This/These diagram(s. EiceDRIVER™ 500 V High-side Driver IC with typical 1.6 A source and 3.3 A sink output currents. It comes with a functional levelshift PDIP8 package and works with IGBTs and MOSFETs. Features: Adjustable Shutdown, Current sense, Enable, Fault reporting, Over-current protection (ITRIP), Single input.

IR2110 Introduction

In many applications MOSFETs configured as high-side switches and many times, it is configured as high-side and low-side switch. In such applications high-low side MOSFET drivers are used. IR2110 is the most popular high and low side driver IC. The IR2110 is a high voltage, high-speed power MOSFET and IGBT drivers with independent high and low side referenced output channels. Proprietary HVIC and latch immune CMOS technologies enable ruggedized monolithic construction. Logic inputs are compatible with standard CMOS or LSTTL output, down to 3.3V logic. The output drivers feature a high pulse current buffer stage designed for minimum driver cross-conduction. Propagation delays are matched to simplify use in high-frequency applications. The floating channel can be used to drive an N-channel power MOSFET or IGBT in the high side configuration which operates up to 500 or 600 volts.

IR2110

Simple demonstration of connecting the IR2110 to a mosfet and control a 12V car light.

Catalog

IR2110 Pin Configuration and Functions

Pin Functions:

IR2110 Functional Block Diagram

IR2110 Parameters

| Parameters | IR2110 |

|---|---|

| Channels | 2.0 |

| Configuration | High-side and low-side |

| Input Vcc min max | 10.0 V 20.0 V |

| Isolation Type | Functional levelshift |

| Output Current (Source) min | 2.5 A 2.0 A |

| Output Current (Sink) min | 2.5 A 2.0 A |

| Turn Off Propagation Delay max | 94.0 ns 125.0 ns |

| Turn On Propagation Delay max | 120.0 ns 150.0 ns |

| UVLO Input (On) | 8.5 V |

| UVLO Input (Off) | 8.2 V |

| UVLO Output (On) | 8.6 V |

| UVLO Output (Off) | 8.2 V |

| Voltage Class | 500.0 V |

IR2110 Features

- Floating channel designed for bootstrap operation

- Fully operational to +500 V

- Fully operational to +600 V version available (IR2113)

- dV/dt immune

- Gate drive supply range from 10 to 20 V

- Undervoltage lockout for both channels

- 3.3 V logic compatible

- Separate logic supply range from 3.3 V to 20 V

- Logic and power ground + /- 5 V offset

- CMOS Schmitt-triggered inputs with pull-down

- Cycle by cycle edge-triggered shutdown logic

- Matched propagation delay for both channels

- Outputs in phase with inputs

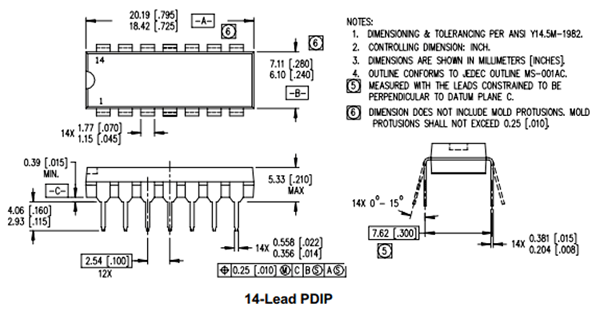

IR2110 Package Outline

- 14 Lead PDIP

- 16 Lead SOIC

Ir2110 Dead Time

How to Use IR2110

Ir2110 Mosfet Driver Circuit Diagram Schematic

Application circuit for driving MOSFETs in both high and low side configurations using IR2110 is given below. The floating channel used to drive the N-channel power MOSFET or IGBT in the high side configuration that operates up to 500 volts. HO and LO are Low side gate drive output and High side gate driving output pins.

IR2110 Functional Equivalents

IR2110 Applications

- DC motor driver

- AC Motor Speed control

- Half, full and three-phase bridge

- Pure sine wave inverter

- Soft starter for three-phase induction motor

IR2110 Popularity by Region

Component Datasheet

IR2110 Datasheet

| Photo | Mfr. Part # | Company | Description | Package | Qty | Pricing (USD) | |||||||||||

| IR2110STRPBF | Company:Infineon Technologies | Remark:IC GATE DRVR HALF-BRIDGE 16SOIC | Package:16-SOIC (0.295', 7.50mm Width) | DataSheet | In Stock:1000 Inquiry | Price:

| Inquiry |

Ir2110 Circuit

Few days ago, GoHz made a 24V 2000W power inverter in home, sharing some design schematics and circuit diagrams.

Power inverter testing. The picture was taken in short-circuited.

Output waveform. The SPWM accuracy of EG8010 was not high enough waveform, so the inverter output was not good enough as pure sine wave. The dead zone time was a bit long (1uS), where the zero-crossing point did not look good, in order to ensure the safety of the tube, GoHz did not adjust it.

This was a full load test on the power inverter, two water heaters, about 2000 watt, the water was boiling completely. Maximum connected load was 3000 watt for approx 10 seconds, due to the DC power supply limitation (paralleling a large DC battery and two small batteries), GoHz did not continue test it. Adjust the inverter power limitation potentiometer, limit the maximum power at 2500 watt, (a little greater than 2500 watt), the power inverter works for less than two seconds before it turn off the output. Short circuit protection is also set about two seconds to turn off the output. Due to the EG8010 programming reason, the power inverter will continuous work after a few seconds if the power supply is not cut off. This power inverter has a good starting ability, it only takes about 1 second for two parallel 1000 watt solar lamps. This inverter is designed to power about 2200 watt, the headline of this paper is 2000 watt is because the DC power supply maximum output current is 100A, so GoHz tested it at 2000 watt, for more than 12 hours testing, it can work well at 2000 watt, there would be no problem for the actual load at 2500 watt.

This is the foreline tube D level waveform when the power inverter was in 2000w full load.

Expanding the foreline tube D level waveform when the inverter in 2000w full load.

This is the power inverter in no-load power consumption test.

It can be seen from two multimeter, no-load power consumption is 24.6 * 0.27 = 6.642W, no-load consumption is relatively low, it can be used for photovoltaic, car batteries and other new energy systems.

Forward toroidal transformer. Stacked two 65 * 35 * 25mm ferrite ring, primary 3T + 3T with 16 1mm wires, the secondary was used very fine multi-strand wire tangled wound of 42T, auxiliary power 3T.

Using 4 pairs ixfh80n10, 80A, 100V, 12.5 milliohms resistors. Rectifiers are 4 set MUR1560, two large electrolytic 450V470uF, 4 35V1000uF Japanese chemical capacitors for 24V DC input.

Backward power tube is 4 set FQA28N50, output inductor is sendust 52mm with 1.5mm enameled wire wrap 120T, inductance 1mH, capacitors are 2 set 4.7uF safety capacitors. Two high frequency arm FQL40N50, and two low frequency arm FQA50N50.

Short circuit test. This power inverter is sensitive in short circuit protection, after more than 100 times short circuit tests (power on short circuit, no-load short circuit, full load short circuit, loading short circuit), the power inverter is still work good. The output terminals of the inverter and the tweezers were scarred.

Here is the circuit section, get understanding the basics of this power inverter, DIY an inverter now.

Forward board DC-DC power circuit board, conventional push-pull. (Download PDF file)

Forward DC-DC circuit driver schematic. It has undervoltage, overvoltage, overcurrent protection, overcurrent protection is implemented by test tube drop. The circuit is conventional SG3525 + LM393. (Download PDF file)

Backward DC-AC schematic, using conventional circuit too, there is nothing new places, the unique is the additional high-voltage detection circuit, means when the DC voltage is higher than 240V DC, the auxiliary power is turned on, and the backward circuit is beginning to work. In debugging, add a function of turning off the SPWM drive circuit when the auxiliary power drops, to prevent the inverter bombing incidents when the auxiliary power supply drops but the DC voltage was still high, by adding this function, we can shut down the power inverter in short circuit. (Download PDF file)

SPWM driver board circuit, EG8010 + IR2110, to detect the voltage drop for short circuit protection. (Download PDF file)

Ir2110 Schematic

Related paper: Car Power Inverter Buying Guide

Ir2110s Pdf

Buying a pure sine wave inverter on GoHz.com, 300w inverter, 500w inverter, 1000w inverter...